| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : SZGH

Model Number : SZGH-CNC1000MDcb-4

Certification : CE

Place of Origin : Shenzhen, China

MOQ : 1 set

Price : negotiation

Payment Terms : TT in advance / Western Union / Paypal /LC/Alipay/Creditcard/MoneyGram

Supply Ability : 300 sets per month

Delivery Time : within 3-5 days upon receipt of full payment

Packaging Details : with international standard carton and wooden packaging

Axis No : 4 axis

displayer : 800*600 8.4 inch real color LCD displayer

function : ATC,PLC and macro function

basic I/O : 56*32

Warranty time : 2 years

type : high classes

store room : 64MB memory, 32Mb user store room

1) The four axes of X,Y,Z,A control, four axes linkage movement.

2) 2ms interpolation cycle,1um precision.

3) 5MHz Output Pulse Frequency,Maximum speed: 300m/min,Feeding speed: 150m/min

4) Multiple function,it can realize the drilling/boring,roughing of roun groove/rectangle groove,finishing of full circle/rectangle,continous drilling of straight line/rectangle/arc etc.

5) Built-in standard PLC program,and can be customized edited according to customer's askes.

6) Memory Capacity: 64MB,User Store Room: 32MB.

7) 8.4 inches(800*600) real colour LCD displayer.

8) Support Metric system/Inch System,with function of auto charfering.

9) Display in Chinese and English,which can be selected by paramter.

10) With USB interface,support USB file processing,software upgrade.

11) DNC in high speed,realize part program real-time transmission processing.

12) Analog voltage output of 0V~10V in two channels,support two-spindle control.

13) Support external MPG.

14) Basic I/Os: 56*40, 40*32 can be edited freely.

Application: CNC Machine Center; Milling Center; CNC milling machinery; CNC drilling machinery; CNC boring machinery; wood working machine; numerically control grinder.

Standard G codes list:

| G code | groups | function | ||

| G00 | 01 | Fast decides | ||

| G01 | The straight line inserts makes up | |||

| G02 | Inserts along the circle makes up/the spiral line to insert makes up CW: The spiral motion spiral line inserts makes up the 2 circular arcs insert makes up the axis synchronization migration other axes. The instruction method only is simply adds on is not the circular arc inserts makes up the axis the shifting shaft | |||

| G03 | The counter circle inserts makes up/the spiral line to insert makes up CCW | |||

| G04 | 00 | pause | ||

| G15 | 17 | Polar coordinate instruction cancellation | ||

| G16 | Polar coordinate instruction: The polar coordinate (radius and angle), the angle to is chooses the plane the first axis to anti-clockwise changes, but the negative direction is clockwise changes . Form : G** G## G16 G00 IP G**Expresses the plane chosen G## mean G90Work piece coordinate system original point G91Current position Assigns the polar coordinate and zero point | |||

| G17 | 02 | Choose the X Yplane | XX axis or its parallel axis YY axis or its parallel axis ZZ axis or its parallel axis | |

| G18 | Choose the Z X plane | |||

| G19 | Choose the Y Z plane | |||

| G20 | 06 | Inch input | ||

| G21 | Millimetre input | |||

| G28/G281/G282/G283/G284 | 00 | Go to first reference point | ||

| G30/G301/G302/G303/G304 | Go to 2,3,4 reference point | |||

| G26 | ZXY axis go to program original point | |||

| G261 | X axis go to program original point | |||

| G262 | Y axis go to program original point | |||

| G263 | Z axis go to program original point | |||

| G264 | A axis go to program original point | |||

| G265 | B axis go to program original point | |||

| G40 | 07 | Cancel tool radius compensate | ||

| G41 | tool radius compensateleft | |||

| G42 | tool radius compensateright | |||

| G43 | Tool lenthen positive compensate | |||

| G44 | 08 | Tool lenthen negative compensate | ||

| G45 | 00 | Tool adding offset | ||

| G46 | Tool subtact offset | |||

| G47 | Tool adding two multiple offset | |||

| G48 | Tool subtact two multiple offset | |||

| G49 | 08 | Cancel tool lengthen compensate | ||

| G37 | 11 | Cancel scale zoom | ||

| G36 | Enable scale zoomformatG36 X_Y_Z_R_ | |||

| G12 | 22 | Cancel programmer mirror | ||

| G11 | Enable programmer mirror | |||

| G52 | 00 | Set local coordinate | ||

| G53 | 14 | Chocie coordinate | ||

| G54 | Chocie work coordinate 1 | NoteThese six work coordinate save in CNCuser may choice any one | ||

| G55 | Chocie work coordinate 2 | |||

| G56 | Chocie work coordinate 3 | |||

| G57 | Chocie work coordinate 4 | |||

| G58 | Chocie work coordinate 5 | |||

| G59 | Chocie work coordinate 6 | |||

| G60 | 15 | exactitude stop | ||

| G64 | Continue path work | |||

| G68 | 16 | rotate coordinateformat G17 G18 G68 a-b- R-; R:Angle G19 | ||

| G69 | Cancel rotate coordinate | |||

| G73 | 09 | Drill deep hole cycleformat G73 X-Y-Z-R-Q-F- L - Zdistance from R to hole bottom Rdistance from original to R Qfeed depth every time Ffeed speed Lrepeat time | ||

| G74 | Left Tap cycleformatG74X-Y-Z-R-P-F- L - | |||

| G80 | Cancel cycle mode | |||

| G81 | Drill cycleformat G81 X-Y-Z-R-F- L - | |||

| G82 | Drill cycleformatG82 X-Y-Z-R-P-F- L - | |||

| G83 | Drill cycleformat G83 X-Y-Z-R-Q-F- L -P- | |||

| G84 | Right Tap cycle formatG84 X-Y-Z-R-P-F- L - | |||

| G85 | Drill cycleformat G85 X-Y-Z-R-F- L - | |||

| G86 | Drill cycleformatG86 X-Y-Z-R-F- L - | |||

| G89 | Drill cycle G89 X-Y-Z-R-P-F-L- | |||

| G90 | 03 | Absolute program | ||

| G91 | Increase program | |||

| G98 | 10 | Go back to origorinal point | ||

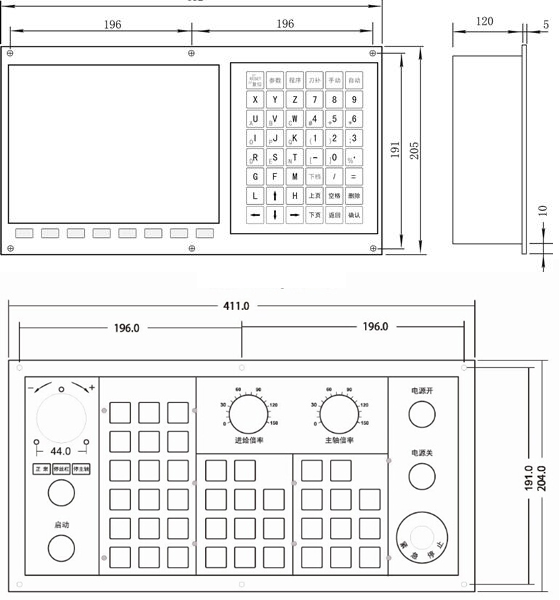

Product Size or drawing:

SZGH-CNC1000MDcb

• Certified actual products - We have a zero-tolerance policy for asset recovery vendors.

• Lowest package prices -Always offer lower price than other companies.

• Professional technical engineer team- possible fastest response and support to client’ application demand.

• Quality guarantee – Free, one-years warranty and life-long maintenance. Any quality problem, SZGH promise to refund.

• Fast, professional and reliable International delivery – flexible and low cost delivery solution for clients.

• Free payment mode by T/T, L/C, western union and Paypal can be available.

Product line:

Delivery Detail: Normally ready goods and stock within 2-5days

|

|

Popular High Class Milling Machining Center CNC Board Controller CNC1000MDCB -4 Usb Interface Images |